120KW machine?can do a?thick steel plate,?round bar?steelproducts such as?diathermy,?has?very high practicability?inthe field?of steel?forgings.

In?Shandong steel?factory?had a?tooling:

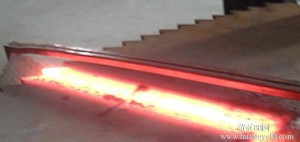

High frequency?quenching?furnace?square?pillow

The?tooling?following the?induction coil,?the?steel?is heated to a certain temperature,?and then?is connected with a water tank,?by quenching,?the?workpiece?is composed of?Henan?Feng electrical?engineering?do,?can be very good to?meet customer requirements,?heating and cooling?in the same position,?noteven?prevent?quenching.

]]>

Large machines?designed to?split?type,?solves the problem ofhandling?large machinery and equipment,?industrial?blue tones,?with three?meter?meter box,?power output?andadjustable temperature.

Model WH-VI-100?high frequency furnace?has a special?positionin the automotive industry.?Because the?automobile parts?andcomponents?need?super abrasion,?fine,?rapid heating and?high frequency?furnace,?can effectively avoid the?workpiecedeformation:

Auto parts?quenching:

Quenching of automobile?parts

This is?the car?front?wheel,?turbine shaft?quenching.?To increase the surface?abrasion resistance.

High frequency?quenching?furnace?don’t tube:

The workpieces of this?picture?from Hebei?Cangzhou customers,requirements are the?inner wall?quenching,?the?induction coil in the?pipe?interior,?from the color?can see,?heating high-frequency?furnace?is?heated?to?the point,?not?scattering,which can meet the?needs?of the majority of customers?hard.

]]>

The characteristics?and parameters of 120KW?high frequency furnace:

1,?power:?than the?electron tube?power 30%,?than frequencypower?SCR?20%.

2,?stable performance,?full protection,?no worries.

3,?heating speed,?no oxidation?layer,?small deformation.

4,?small volume,?light weight,?convenient installation.

The 5,?sensor isolation by transformer,?safety.

6,?environmental protection:?no?pollution,?noise and dust.

7,?strong adaptability?to?various:?workpiece heating.

8,?the temperature?and the heating time?can be controlled accurately,?high machining quality.

Main application:?heat treatment?quenching machine guide,automobile,?motorcycle,?wrenches and other parts.?Bolt,?nutlarger diameter?of hot upsetting,?crankshaft,?camshaftsprocket gear?quenching,?quenching,?the metal belt?hot plating,?heat treatment of steel wire,?nonferrous metalsmelting.

Model /?configuration 120

The working power?three-phase?380V/50HZ

Working voltage 342V-430V

The maximum input?current 165A?bus

The maximum output?current of 120KVA

The oscillation frequency?of 15-35KHZ

The efficiency of 100%

Load sustained rate of 100%

The cooling?water flow rate 28Lmin?(0.1MPa)

Cooling water pressure?0.1-0.3mp

Host weight?85kg

The weight of?90kg?transformer

Machine dimension?650*520*1100

Transformer?size?500*800*580

The host?color?blue?/ white

Transformer?color?blue?/ white

Special?application field of?auto parts,?cam?shaft,metallic?diathermy

The water temperature?at 50?℃?protection

]]>