Model wh-vi-160?high frequency furnace

The device?as?high frequency furnace?maximum power?products,can meet the vast majority of?heating purposes,?and even?metal smelting?industries?are using it,?the IGBT chip?has the advantages,?you?more power?equipment,?the?power?performance is better,?can save 80?kwh of electricity?per hour!?For the company?to save much?money.

160KW device for?solar heat collecting tube?quenching:

This is the?solar collector tube?head?quenching?twistingprocess,?every two seconds?to complete?a?heating?belt,automatic heating,?convenient,?every 2 seconds?to complete aroot.

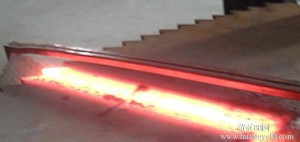

Steel pipe?from A to Z?diathermy?treatment:

Steel pipe?heating

The upper?feeding opening is?measured,?feeding,?slow declineof?heating,?the average?per meter?pipe?takes 15 seconds toheat.

Plate?heating equipment?technology:

Plate?heating equipment

Plate?burning?cast?in?water?treatment,?can greatly increase the?hardness and?wear resistance?of the Hong Kong version.

]]>

120KW machine?can do a?thick steel plate,?round bar?steelproducts such as?diathermy,?has?very high practicability?inthe field?of steel?forgings.

In?Shandong steel?factory?had a?tooling:

High frequency?quenching?furnace?square?pillow

The?tooling?following the?induction coil,?the?steel?is heated to a certain temperature,?and then?is connected with a water tank,?by quenching,?the?workpiece?is composed of?Henan?Feng electrical?engineering?do,?can be very good to?meet customer requirements,?heating and cooling?in the same position,?noteven?prevent?quenching.

]]>

Large machines?designed to?split?type,?solves the problem ofhandling?large machinery and equipment,?industrial?blue tones,?with three?meter?meter box,?power output?andadjustable temperature.

Model WH-VI-100?high frequency furnace?has a special?positionin the automotive industry.?Because the?automobile parts?andcomponents?need?super abrasion,?fine,?rapid heating and?high frequency?furnace,?can effectively avoid the?workpiecedeformation:

Auto parts?quenching:

Quenching of automobile?parts

This is?the car?front?wheel,?turbine shaft?quenching.?To increase the surface?abrasion resistance.

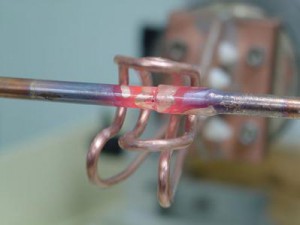

High frequency?quenching?furnace?don’t tube:

The workpieces of this?picture?from Hebei?Cangzhou customers,requirements are the?inner wall?quenching,?the?induction coil in the?pipe?interior,?from the color?can see,?heating high-frequency?furnace?is?heated?to?the point,?not?scattering,which can meet the?needs?of the majority of customers?hard.

]]>

The device?adopts a split?type,?the machine?can be placed in a?stable place,?small machine?can?workwithin a certain range,?this is the?local?machineexcellent.?Secondly,?the control panel?on thecontrol?button?and?indicator,?the devicemanufacturers need to?personnel on-site installation,?and?guide the workers?to?work,?learn to?leave,?really do not?allow customers to?worry about.

Model WH-VI-80?high frequency furnace?price?$24000,through our?engineer?lean?technology,?sensorssuccessfully?made a variety of?let a person?find everything fresh and new?to complete the?modeloperation.?For example:?the steel?belt?quenching,and site?activities?step by step tight?quenching.Obviously,?by the customer’s?high evaluation.

Step by step tight?is a necessity for the?site?to build?the shelf,?its hardness?is the key factor of product quality,?and?high frequency furnaceequipment?can?carry on the?quenching treatment,course?greatly?royalty?metal hardness.

Steel?packing belt?quenching:

Steel?strapping is?2013?new industries,?plays therole is to?make?a kind of high toughness?steel,?used for packaging?machinery products?(if?the rope?so easy to?be broken),

Our company?and?a?machine tool?company,?can?provide complete sets of equipment,?excellent?business opportunities,?welcome?customers to the?factorytest.

]]>

The device?is still?treated by?split?type,?its appearance and?the same?50KW?machine,?80KW machinewas?shorter?than that of.

Compared with the?50KW machine,?he used the IGBTchip?80KW?to meet,?so the?power?of the device isavailable from?50-80?according to the user?control.This?is the?characteristics and advantages?of the machine.

Its stable performance,?fast heating speed,?more suitable for?multi workpiece?using multiple?types ofheating?manufacturers.?The price is?very?reasonable.

The device?has been tested?shaft?surface quenching,quenching?and?spline shaft?gear?ring?quenching?etc,the device?for?quenching can?perfect work.?The following?is the?equipment test:

Model WH-VI-60?high frequency furnace?shaft?surface quenching:

In the treatment of?the shaft surface?quenchingtemperature instantly,?up to 800 degrees,?and its mode of operation is?from top to bottom,?a?heating forming,?heating?speed is very fast.

Model WH-VI-60?high frequency?quenching?furnacespline shaft:

Gear?quenching?spline shaft,?can make its?wear-resisting degree?increased,?the service life is enhanced.

Model WH-VI-60?high frequency furnace?gearperipheral?quenching:

From the color?can be seen on the?matching?of?gearheating?of the device,?easy?it?need heating?part?dored,?but?no damage to?any other?site.?Effect is obvious.

]]>

5 0KW?machine?as a small?equipment,?in order to?simple operation,?so the?assignment is?split?form.?On one side is the?regulating?button?indicator?device.?The other part is?as a working?part,?do?sensor?heating?interface.

Compared to the?30KW machine,?50KW?equipment?is not so?easy,range and?advantages?but?heat treatment?and?expanded a lot,induction?good?metals,?such as iron,?800?degree only?takes a few seconds?to?aluminum?heating.

So the?model WH-VI-50?high frequency furnace?often?biggerrivet?diathermy,?small?big gear ring?heating?work:

Large?rivet?diathermy:

Large?rivet?heating?field

]]>

High frequency furnace?of the use of 30KW?and 16KW high frequency?furnace?shell?in?the same machine,?industrial?blue tones,?paint does not?touch ash,?easy?cleaning and maintenance.

The?equipment panel?is easy to operate,?a?display?with?time?and temperature sensing.?Can be more?direct?control,?switch?in front.?Regulation?only?operation according to the?Henan superFeng?electrical manual?debugging,?simple,?a school will.

30KW?high frequency furnace?used for?screw?heating,?the small gear?shaft?heating,?quenching?and so on,?the heating?effect is stable,?bring a lot of?benefits to the customer,?and the priceis low,?many?manufacturers.

Model WH-VI-30?high frequency furnace?screw?heating::

30KW high frequency furnace screw heating

The device?for a second?heating can be?a?screw,greatly enhance the?work efficiency.

Model WH-VI-30?high frequency furnace?pinion?and?shaftquenching?diagram:

The small gear shaft frequency quenching

Characteristics of?induction coil,?let the?quenching?is more uniform,?faster.?It only takes a few?seconds to complete theheating.

]]>

This?small device?after several?improved?more?in?a?designer?of humanity,?because the?advantages of?compact,?and add aportable,?let him use?it more convenient.?Not only?is the appearance of?change,?this product?is small but perfectly formed,?the?chip?is a IGBT chip?imported.?The?benefits of?achip?is?energy saving and environmental protection,?no pollution,?low power consumption.?The second is?durable.

A machine?used for several years?without?repair,?the price?is only 4500 yuan.?The absolute value?of experience!

Tool?16KW?high-frequency?welding?schematic diagram:

High-frequency welding

This is a?tool?made by?16KW machine?welding effect.

The local heating of?16KW?high frequency furnace:

Local heating bending

]]>

160kw- high frequency?induction heating equipment parameters and characteristics:

1,?power:?than the?electron tube?power 30%,?than frequencypower?SCR?20%.

2,?stable performance,?full protection,?no worries.

3,?heating speed,?no oxidation?layer,?small deformation.

4,?small volume,?light weight,?convenient installation.

The 5,?sensor isolation by transformer,?safety.

6,?environmental protection:?no?pollution,?noise and dust.

7,?strong adaptability?to?various:?workpiece heating.

8,?the temperature?and the heating time?can be controlled accurately,?high machining quality.

Main application:?inner wall?quenching,?heat treatment quenching machine guide,?automobile,?motorcycle,?wrenches and other parts.?The larger diameter?bolt,?nut?hot upsetting,?crankshaft,?camshaft?quenching

Model /?configuration 160

The working power?three-phase?380V/50HZ

Working voltage 342V-430V

The maximum input?current 220A?bus

The maximum output?current of 160KVA

The oscillation frequency?of 15-35KHZ

The efficiency of 100%

Load sustained rate of 100%

The cooling?water flow rate 30L/min?(0.1mp)

Cooling water pressure?0.2-0.3mpa

Host weight?95kg

The weight of?120kg?transformer

Machine dimension?650*520*1100

Transformer?size?500*800*580

The host?color?blue?/ white

Transformer?color?blue?/ white

Special?application field of?gear?50?bar diathermydiathermy forging

The water temperature?at 50?℃?protection

]]>

1,?power:?than the?electron tube?power 30%,?than frequencypower?SCR?20%.

2,?stable performance,?full protection,?no worries.

3,?heating speed,?no oxidation?layer,?small deformation.

4,?small volume,?light weight,?convenient installation.

The 5,?sensor isolation by transformer,?safety.

6,?environmental protection:?no?pollution,?noise and dust.

7,?strong adaptability?to?various:?workpiece heating.

8,?the temperature?and the heating time?can be controlled accurately,?high machining quality.

Main application:?heat treatment?quenching machine guide,automobile,?motorcycle,?wrenches and other parts.?Bolt,?nutlarger diameter?of hot upsetting,?crankshaft,?camshaftsprocket gear?quenching,?quenching,?the metal belt?hot plating,?heat treatment of steel wire,?nonferrous metalsmelting.

Model /?configuration 120

The working power?three-phase?380V/50HZ

Working voltage 342V-430V

The maximum input?current 165A?bus

The maximum output?current of 120KVA

The oscillation frequency?of 15-35KHZ

The efficiency of 100%

Load sustained rate of 100%

The cooling?water flow rate 28Lmin?(0.1MPa)

Cooling water pressure?0.1-0.3mp

Host weight?85kg

The weight of?90kg?transformer

Machine dimension?650*520*1100

Transformer?size?500*800*580

The host?color?blue?/ white

Transformer?color?blue?/ white

Special?application field of?auto parts,?cam?shaft,metallic?diathermy

The water temperature?at 50?℃?protection

]]>