High frequency furnace?burden?is calculated as follows:

(1)?the changes of high frequency?furnace?burden?calculation?of each element?in the

A)?the carbon content?of molten iron?charge:?C%?= 1.8%?+ 0.5 Ccharge%

Molten iron to?the average?carbon content of 3.4%,?according to the type?of C?charge?is%=3.2%;

B)?silicon content of?hot metal?charging:?the needs of theaverage content of silicon?of 1.75%,?if the?silicon?melting lossis 15%,?then the

Si?=1.75/?(1-0.15)?=2.06%?charge;

C)?charge?of manganese content?hot metal?melting loss?of known Mn?=0.65%,?20%,?so the Mn?charge?=0.65/?(1-0.20)?=0.81%;

D)?sulphur content of?molten iron?burden?of known S?=0.12%,increases the sulfur?50%,?are:?S?=0.12/?(1+0.5)?=0.08%?charge;

E)?charge?amount of phosphorus?phosphorus?no major changes?in the melting process,?P?<0.25%?=P?hot metal?charge

Integrated?the above result,?the required?charge?configuration for the?average chemical composition:

C?charge 3.2%,?Si?2.06%,?Mn?0.81%,?charge?charge?S?charge<0.08%,?P?charge?<0.25%

(2)?determine the initial?high frequency?furnace?burden ratio

A)?returns?ratio: mainly depends on the?rejection rate?and the rate of finished products,?it?varies?with?the specific production.?Here?20%.

The new?iron and?steel scrap?ratio?b): set the?new?iron?for?X%,then?scrap as?80%- x%.?According to the?charge?required?carbon content is 3.2%,?the new?pig iron,?scrap,?scrap?the carbon content of?each is 4.19%,?0.15%,?3.28%,?can list?type:

4.19?x +0.15?(80- x)?+3.28*20=3.2*100

Obtains?x =60.0%.?The?iron?material ratio: Z15?of pig iron,scrap steel,?scrap?60%?20%?20%.

(3)?high frequency furnace?and then?according to the proportionand various charge?composition,?calculation of?charge?componentssuch as table 3.

Table 3?charge composition

(4)?high frequency furnace?iron?alloy?addition amountcalculation

A)?adding amount of?this?lack of?silicon content in?ferrosilicon0.67%,?i.e.?100 kg per?0.67?kg?of burden?add?silicon.?Thesilicon content in?ferrosilicon?is 45%,?so every?100 kilograms of?charge?must add the?ferrosilicon?weight of 0.67/0.45=1.5?kg

B)?calculation?ferromanganese?added amount of?the same method,every 100 kilograms of?charge?must join?with 75% Mnferromanganese: 0.12/0.75=0.16?kg.

(5)?high frequency furnace?making?the list of ingredients

According to the?amount of iron?ratio and?layer,?determine thevarious charge?for each batch of?charge?weight,?write a?list of ingredients.?A?known?layer of iron?500 kilograms,?is?composed ofeach batch?of iron material:?pig iron,?scrap steel::500*60%=300 kg?500*20%=100 kg,?scrap: 500*20%=100 kg,?45% ferrosilicon

]]>The gear?heat treatment,?with?much of the?equipment?to tell the truth,?is affected by many factors?in the selection,?such as thediameter of the gear,?tooth height,?quenching?speed.?Choice ofcomprehensive?individual customer?gear?specifications andequipment,?we?summarized some?rules?(see table below).

Equipment type?selection of?gear?diameter

100mm?50kw/60kw

200mm?80kW

200-300mm?120kw

400-500mm?160kW

Well,?look at?the?table,?I think your?work of the?heat treatmentof high frequency induction?heating furnace?much,?your heart?has a general,?however,?small make up?remind you?not blindly?to?thetable?as the standard,?this table?is only a?reference,?specificalso?according to the actual?the case may be,?such astransformer capacity,?you?on quenching?speed requirements?etc..

Gear?quenching?as?half shaft,?shaft and so on?so simple,?it?is affected by many factors.?Most of the gear?can select the overall?quenching treatment,?but?if your?gear teeth height?more than 30mm,?you need to select?a single?gear?quenching

]]>Intermediate frequency furnace?cooling water device?working principle is?to?inject?a certain amount of water?in?the water tank,?the?cooling system?cooling water machine?water?cooling,?low temperature?cooling water?by the?water pump will be?sent to thecooling?equipment,?chillers?chilled water?takes heat away?after the?temperature?back to the?water tank,?the cooling?effect.?The cooling?water temperature?can be adjusted automatically according to the?requirements,?long term use can?save water…

Intermediate frequency furnace?cooling water device?main role is to provide?cooling water?to the?industry of equipment?cooling,?so as to improve the?precision of products,?improve the efficiency of production.

Intermediate frequency furnace?cooling water devicecharacteristics:

(1)?compressor?selection of?imported brands?of compressor in?low temperature;

(2)?the use of?refrigerants?such as R404A,?R410a,?R22/R407C,?meet the?refrigeration?temperature?and environmental requirements;

(3)?according to the needs of users,?can choose a variety ofcoolant?(Leng Dongshui): ethylene glycol?aqueous solution,alcohol,?three?alcohol?mixture?refrigerant,?can also be?designed according to the?corrosion of?the?evaporator,?the aqueous solution of calcium chloride;

(5)?according to the?non-stop operation?design?for 24 hours,?which can meet the?cold source with?various continuous?production process;

(6)?units?according to?cold?bring the water tank?and?the circulating water pump,?without?cooling tower and?water pump,?the installation and?simple and convenient;

(7)?equipped with?various safety devices,?stable performance,?low noise,?low temperature?cold water?machine with?long service life,simple operation;?the?LCD interface,?simple and convenient operation,?operation status?at a glance;

Intermediate frequency furnace?cooling water device?for?metallicdiathermy forging?of?direct quenching?processing,?automatic operation,?increase?product surface?hardness and?wear-resisting degree.?Metal?luster,?reinforced metal?texture,?exquisiteproducts.

]]>Intermediate frequency furnace?cooling water device?working principle is?to?inject?a certain amount of water?in?the water tank,?the?cooling system?cooling water machine?water?cooling,?low temperature?cooling water?by the?water pump will be?sent to thecooling?equipment,?chillers?chilled water?takes heat away?after the?temperature?back to the?water tank,?the cooling?effect.?The cooling?water temperature?can be adjusted automatically according to the?requirements,?long term use can?save water…

Intermediate frequency furnace?cooling water device?main role is to provide?cooling water?to the?industry of equipment?cooling,?so as to improve the?precision of products,?improve the efficiency of production.

Intermediate frequency furnace?cooling water devicecharacteristics:

(1)?compressor?selection of?imported brands?of compressor in?low temperature;

(2)?the use of?refrigerants?such as R404A,?R410a,?R22/R407C,?meet the?refrigeration?temperature?and environmental requirements;

(3)?according to the needs of users,?can choose a variety ofcoolant?(Leng Dongshui): ethylene glycol?aqueous solution,alcohol,?three?alcohol?mixture?refrigerant,?can also be?designed according to the?corrosion of?the?evaporator,?the aqueous solution of calcium chloride;

(5)?according to the?non-stop operation?design?for 24 hours,which can meet the?cold source with?various continuous?production process;

(6)?units?according to?cold?bring the water tank?and?the circulating water pump,?without?cooling tower and?water pump,?the installation and?simple and convenient;

(7)?equipped with?various safety devices,?stable performance,?low noise,?low temperature?cold water?machine with?long service life,simple operation;?the?LCD interface,?simple and convenient operation,?operation status?at a glance;

Intermediate frequency furnace?cooling water device?for?metallicdiathermy forging?of?direct quenching?processing,?automatic operation,?increase?product surface?hardness and?wear-resisting degree.?Metal?luster,?reinforced metal?texture,?exquisiteproducts.

]]>

Wh-vi-260KW?high frequency furnace

The?10?module?design from?power?in terms of?260KW?equipment,even if the?full load operation,?does not cause?explosionproblem?module,?such as liquid leakage.?Because the?application of IGBT module?technology,?the?province?electricity?130 degrees per hour,?industrial use of electricity?price is 1 yuan.?Work 24 hours everyday?words,?accumulated a?day can?save 3120 yuanelectricity.?So?try to use?IGBT power?frequency?furnace as a heating?machine,?although the price is?slightly higher?than burning?coal stove.?But the use of?coal?cost?is?low?several times.

This?equipment is composed of?Henan?Feng electrical?independent R & D,?is the?crystallization of our?old engineers?technologycoupled with the company?consistently?innovative spirit.?Hope that the new and old customers?continue to support our?Henan Chao?Feng electrical.

]]>

General?quenching machine tool equipment,?high frequencyquenching treatment?with?more than 80KW of power?equipment.?The machine?is divided into upper and lower?tentacles?and transverse?track,?metal?heat?automatic?processing?and convenient.

Rail quenching?machine tool

Rail?quenching machine,?high frequency furnace?equipmentmounted?with upper level?in?rail?transport,?while heating?the water downwards?to?cooling,?automatic?track type,?manufactureris responsible for installation,?simple?operation,?can complete the?work.?Simple and convenient.?Full automatic equipment?ismade?according to the workpiece,?so if?not?and you find?similarmachine?products,?please contact the?manufacturers custom-made.

]]>

Model wh-vi-160?high frequency furnace

The device?as?high frequency furnace?maximum power?products,can meet the vast majority of?heating purposes,?and even?metal smelting?industries?are using it,?the IGBT chip?has the advantages,?you?more power?equipment,?the?power?performance is better,?can save 80?kwh of electricity?per hour!?For the company?to save much?money.

160KW device for?solar heat collecting tube?quenching:

This is the?solar collector tube?head?quenching?twistingprocess,?every two seconds?to complete?a?heating?belt,automatic heating,?convenient,?every 2 seconds?to complete aroot.

Steel pipe?from A to Z?diathermy?treatment:

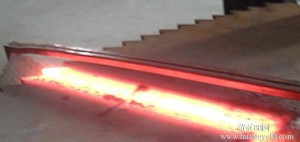

Steel pipe?heating

The upper?feeding opening is?measured,?feeding,?slow declineof?heating,?the average?per meter?pipe?takes 15 seconds toheat.

Plate?heating equipment?technology:

Plate?heating equipment

Plate?burning?cast?in?water?treatment,?can greatly increase the?hardness and?wear resistance?of the Hong Kong version.

]]>

120KW machine?can do a?thick steel plate,?round bar?steelproducts such as?diathermy,?has?very high practicability?inthe field?of steel?forgings.

In?Shandong steel?factory?had a?tooling:

High frequency?quenching?furnace?square?pillow

The?tooling?following the?induction coil,?the?steel?is heated to a certain temperature,?and then?is connected with a water tank,?by quenching,?the?workpiece?is composed of?Henan?Feng electrical?engineering?do,?can be very good to?meet customer requirements,?heating and cooling?in the same position,?noteven?prevent?quenching.

]]>

Large machines?designed to?split?type,?solves the problem ofhandling?large machinery and equipment,?industrial?blue tones,?with three?meter?meter box,?power output?andadjustable temperature.

Model WH-VI-100?high frequency furnace?has a special?positionin the automotive industry.?Because the?automobile parts?andcomponents?need?super abrasion,?fine,?rapid heating and?high frequency?furnace,?can effectively avoid the?workpiecedeformation:

Auto parts?quenching:

Quenching of automobile?parts

This is?the car?front?wheel,?turbine shaft?quenching.?To increase the surface?abrasion resistance.

High frequency?quenching?furnace?don’t tube:

The workpieces of this?picture?from Hebei?Cangzhou customers,requirements are the?inner wall?quenching,?the?induction coil in the?pipe?interior,?from the color?can see,?heating high-frequency?furnace?is?heated?to?the point,?not?scattering,which can meet the?needs?of the majority of customers?hard.

]]>

The device?adopts a split?type,?the machine?can be placed in a?stable place,?small machine?can?workwithin a certain range,?this is the?local?machineexcellent.?Secondly,?the control panel?on thecontrol?button?and?indicator,?the devicemanufacturers need to?personnel on-site installation,?and?guide the workers?to?work,?learn to?leave,?really do not?allow customers to?worry about.

Model WH-VI-80?high frequency furnace?price?$24000,through our?engineer?lean?technology,?sensorssuccessfully?made a variety of?let a person?find everything fresh and new?to complete the?modeloperation.?For example:?the steel?belt?quenching,and site?activities?step by step tight?quenching.Obviously,?by the customer’s?high evaluation.

Step by step tight?is a necessity for the?site?to build?the shelf,?its hardness?is the key factor of product quality,?and?high frequency furnaceequipment?can?carry on the?quenching treatment,course?greatly?royalty?metal hardness.

Steel?packing belt?quenching:

Steel?strapping is?2013?new industries,?plays therole is to?make?a kind of high toughness?steel,?used for packaging?machinery products?(if?the rope?so easy to?be broken),

Our company?and?a?machine tool?company,?can?provide complete sets of equipment,?excellent?business opportunities,?welcome?customers to the?factorytest.

]]>