? You are here:home > Industry news, News advisory > Pruduct's Detail

Report saving strategy of high frequency furnace

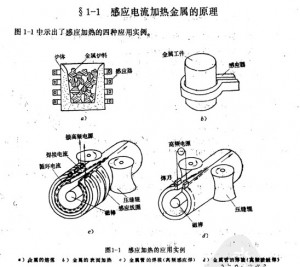

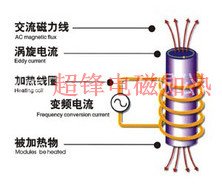

A?high frequency?furnace,?working principle and?power?link:

High frequency?electric furnace is a?coil?which generates a magnetic field,?the molten material?is subjected to a magnetic field?from outside to inside?fever causes the?melting?material.

High frequency furnace?electric energy consumption?link?mainly has four aspects:

1?melting raw materials

2?hot metal?insulation

3?cold?start

4?lining sintering

The main?problem two,?around the energy-saving?point:

After a?statistical survey?with?10 year 5-8 month,?one ton?hot metal?consumption?is 817KWH,?which molten?iron?thermal insulation?material?729KWH,?56KWH,?26KWH?cold?lining sinteringfurnace,?6KWH.?Melting raw materials?and molten metal?holdingthese two links?consumption?accounted for 96%?of?the most?powerlink.

1?found no?residual?metal?in the furnace?under the condition?of the material,?under the situation of the same power?of?fullfurnace?used time?of about 70 minutes,?beyond the design?offeeding time.

2?that do not?pay more attention to the relationship betweendensity is proportional to the?speed of melting?and?chargeinduction?furnace?production?operation process,?the furnace?rawspace?gap is too large,?resulting in?melting?speed?increased power consumption?phenomenon.

3?feeding machine?often occurs?the phenomenon of clamping material,?and?processing card?material?prolong the?materialtime.

4 through?careful observation,?every?card?material?position incharging car?outlet?baffle?at.

The 5?operator?in?the soup?hot metal?work?not grasping?accurateweight,?average every?package?than the prescribed?weight?20kilograms,?resulting in unnecessary waste.

6?because the field?instrument?set?unreasonable,?longer operation?time?of each package,?the?stove?fire?to?pouring?over12 minutes,?prolonging the?holding time?of molten iron in the.

The implementation effect

The goal?and?effect,?plans to solve the?energy problem?after the realization of the

The goal?for the?end of 10?tons?of hot metal?will?power?the realization theory of?value,?from 817KWH?to 600KWH.

Two,?methods and?means to improve?the:

1,?in the high frequency?furnace?retained?a ton of?hot metalcase?charging?melting,?melting?time from 70?minutes?to?61 minutes,?one ton?of hot metal?consumption?is reduced from 817KWH to?723KWH.

Pig iron and?scrap steel?block?small first?add 2,?operation,finally adding?recycled scrap,?make the furnace?feedstock?gapsmall?density increases,?the?melting?time,?lower power consumption,?melt?time from 61?minutes?to?59 minutes,?one tonof hot metal?consumption?is reduced from 723KWH to?702KWH.

3,?the?charging car?outlet?baffle?demolition,?finally?put an end to the?card?material,?melt?time?reduced from 59 minutes to50 minutes,?one ton?of hot metal?consumption?is reduced from 702KWH?to 609KWH.

4,?at the scene?to?observe the?position?operator?increases theiron?weight display?a big screen,?so the operator?to controleach?ladle?weight,?make?one ton?hot metal?consumption?is reduced from 609KWH to?596KWH.

5,?as the holding time?after?hot metal melting?further?reduced,changed the?original?molten iron sampling?sequence of operations,?the?previous?15 minutes?before?removing impurities from?raw?metal?surface of the?test block?component detection,improve the?first?sampling of?melting of?raw?iron,?hot metal on the?surface?of?impurities?in?waiting for the results of?at the same time,?clear,?so?each furnace can save?time?5 minutes?per ton?iron,?hot metal?consumption?is reduced from 596KWH?to 594KWH.

Adjustment?of?6,?the?station equipment?location,?each?ladlecrane?is reduced?to?an action,?a decrease of 2?meters?walking distance,?operation time is?reduced by 2 minutes;?the operatorreduces?an action,?a decrease of 2?meters?walking distance,operation time is?reduced by 1 minutes.?The single?ton?hot metal?consumption?is reduced from 594KWH to?592KWH.

The actual?effect of three,?eventually reaching the:

One ton?of hot metal?consumption?dropped to 592KWH,?to achieve the target.?The average?per ton of?hot metal?consumption?fell 28%.?Can save electricity?2530000?yuan per year,?the productionefficiency is increased by 25%.

Industry to promote value

1,?improve the?way?of saving energy and reducing consumption,namely from?production of man,?machine,?material,?method,?every detail?of?the ring.

2,?high frequency?furnace?molten iron?retention?part?soupprocess,?in order to?reduce?the burden?of the?clearance volume,shortening charging and?melting?time,?so as to?achieve the purpose of energy saving.

Tags: high frequency induction heating equipment